Carbon footprint in the packaging industry

Launched in 18th-century Britain, the Industrial Revolution significantly affected the rate of population growth worldwide. The ever-increasing sum of needs (consumption processes) is inextricably linked to the need to multiply production processes. Their impact is not indifferent to the environment. Earth's natural resources are gradually being depleted, and the concept of carbon footprint is gaining importance.

The origin of the term

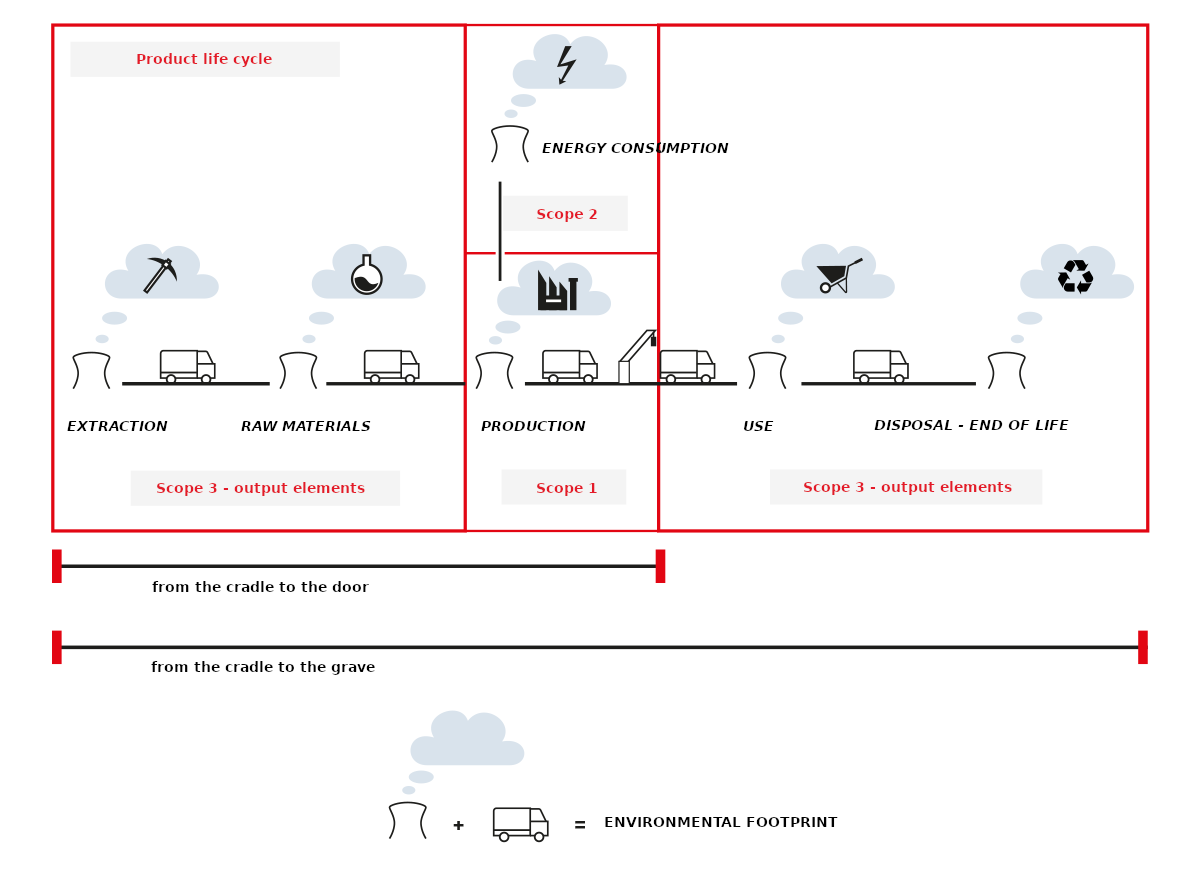

The general rule says that a carbon footprint is the total sum of greenhouse gas emissions caused directly or indirectly by an entity, which may be a company, product, service, event, city, municipality, state or individual. The term refers to the oldest yardstick for determining a person's ecological footprint (ecological footprint), which is also part of the so-called footprint family. CF first appeared in the press in 2000, while in specialized literature seven years later. The concept also transformed, taking into account - in addition to carbon dioxide - other greenhouse gases: methane, nitrous oxide, freons, ozone, sulfur hexafluoride. In the study of the carbon footprint, the procedure for measuring it plays a major role.

- The two main methods are:

- LCA (life cycle analysis) - refers to the full life cycle of a specific product. It distinguishes between "cradle to grave" and "cradle to customer door" ranges.

- IPCC (Intergovernmental Panel on Climate Change) - is used to calculate equivalent carbon dioxide emissions. To do this, multiply the emissions of a specific greenhouse gas by a global warming index dedicated to it.

Ne there is a standardized methodology for calculating the carbon footprint. In Poland, an independent specification PAS 2050 - "Publicly Available Specification 2050" is used. However, it uses the available standards ISO 14040 and ISO 14044.

Carbon footprint and glass

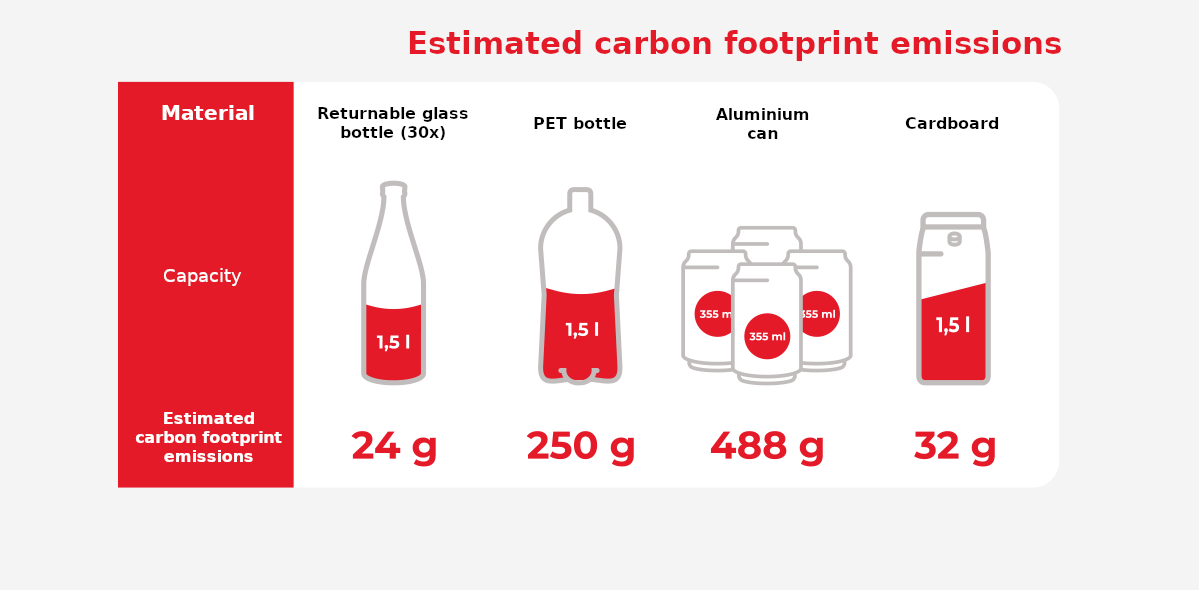

Glass is undoubtedly one of the most environmentally friendly raw materials used in the packaging industry. Its advantages include chemical inertness, hygienic, temperature resistance or recyclability. Unfortunately, there is still a misconception that a quality product must be heavy and solid. This is known to liquor manufacturers, who emphasize the character of the brand with prestigious packaging. According to Grupo ARCE, a company specializing in calculating emissions in the food sector, the carbon footprint of a bottle of wine is 1.2144 kg of CO2, 39% of which is generated by the bottle itself. In comparison, emissions from viticulture and the wine-making process itself are only 15% and 17%, respectively.. Although a glass bottle weighing less than 350 g shows sufficient strength, we can find vessels weighing as much as 2,850 g on the market. The unfavorable situation can be compounded by costly transportation of vessels requiring special protection, the cleaning process and distribution. As a result, a glass bottle can emit up to 4 times more carbon dioxide than a PET bottle. Among the arguments against the use of glass packaging is also the need to melt it. However, excess carbon dioxide emissions from natural gas and chemical reactions occurring between raw materials can be significantly reduced by cullet. Crushed glass does not emit CO2 during melting, and furnaces do not have to burn as rapidly, further saving carbon. According to the European Container Glass Federation (FEVE), an industry group based in Brussels, 10% more cullet in the furnace reduces carbon dioxide emissions by 5% compared to traditional glass production. The advantages of cullet are also demonstrated by the Polish Zero Waste Association: "Every 10% of primary raw materials replaced with cullet yields about 3% energy savings and a 5% reduction in CO2 emissions for making a glass product." They see benefits in the announced deposit system. It is estimated that a returnable glass bottle can replace up to 20 disposable bottles. Statistically, the carbon footprint of a returnable bottle compared to a disposable one is 1:5. Unfortunately, the Polish system is underdeveloped, both from the customer's side (the obligation to show a receipt) and the seller's side (a deposit subject to VAT). This significantly limits its functioning. The average life cycle of returnable packaging is cut in half. Poland's deposit system is to cover reusable glass bottles of up to 1.5l, as well as plastic bottles of up to 3l and metal cans of up to 1l. The deposit rate is to be standardized. The project is expected to take off in 2025.

Positive changes

In the near future, the situation could be completely reversed, and the glass production system could become emission-free. However, immediate changes are needed. Currently, most glass packaging ends up in landfills instead of being recycled. It is worth noting that by reusing the bottle, the GWP (global warming potential), or greenhouse effect potential, is reduced by about 40%. Moreover, recycling bottles and jars saves virgin materials such as sand, limestone and soda ash. EU requirements for waste management are increasing every year. The European Commission's EU Packaging and Packaging Waste Directive (PPWD) requires us to reach recycling levels for container glass of up to 70% in 2025 and 75% in 2030. Member countries and the UK are among the most advanced regions in the world in this regard. Glass produced in the EU contains about 52% recycled material. However, only 31% of glass packaging in the United States is recycled. Countries such as China and Brazil do not release statistics at all. Excess emissions are being fought against by the North American trade association Glass Packaging Institute, which aims to reach 50% by 2030. Such efforts have enormous power, as the Johannesburg-based Glass Recycling Company's project, among others, proves. Through the use of returnable bottles, the organization has managed to increase the recycling rate in South Africa from 18% in 2005-2006 to 42% in 2018-2019.

Source: Consus Carbon Engineering

The energy crisis has contributed in part to the transition. The decarbonization process is expected to be aided by manufacturers who are investing in electrification, biomass and hydrogen-powered furnaces. Well-known brand Absolut Vodka and Swedish glassmaker Ardagh Glass Limmared are working on technology that will reduce the carbon footprint of glass bottle production by 20%. A glass furnace powered in part by hydrogen energy will be built later this year. The hydrogen will be produced directly in Ardagh using renewable electricity. For many British companies, the value of a product's carbon footprint is already more important than the price of the product.

It is difficult to imagine a high-quality wine in plastic packaging. A glass bottle not only emphasizes the qualities of the liquor, but also protects it from external factors. Glass jars remain indispensable for baby food and preserved food storage. Decarbonizing the production of glass packaging is a huge challenge. Cross-industry partnerships are becoming invaluable at this point. Most countries have taken steps to reduce emissions. Worth mentioning are food labels with a carbon footprint, mandatory reporting of the amount of CO2 produced by companies or the anti-waste law passed in France. Returnable bottles have long been used by bottler Uzdrowisko Wysowa S.A. The manufacturer's offer includes iodine-rich mineral waters, a series of medicinal waters and refreshing fruit drinks. It seems that glass is still the future of the packaging industry. However, it requires modernization of the production process and, above all, our habits.

- https://climatestrategiespoland.pl/

- https://glasshallmark.com/glass-packaging-carbon-neutral-future

- https://klimat.rp.pl/ekotrendy/art17079141-te-butelki-moga-zmniejszyc-slad-weglowy-produkcji-wina-o-90)

- https://portalkomunalny.pl/ile-warte-jest-szklo-w-systemie-kaucyjnym-wg-wyliczen-polskiego-stowarzyszenia-zero-waste-156-mln-zl-523897

- https://publicystyka.ngo.pl/system-kaucyjny-bez-szkla-spelnia-tylko-cele-biznesu

- https://sozosfera.pl/srodowisko-i-gospodarka/czym-jest-slad-weglowy/

- https://tappwater.co/en/glass-vs-plastic-vs-aluminium-what-is-the-most-sustainable-choice/

- https://www.ft.com/content/de0061b7-784e-4347-b5b0-64d3d11eeb90

- https://www.nature.com/articles/d41586-021-02992-8

- J. Zarczuk, B. Klepacki,The term, importance and measurement of the carbon footprint, Economics and Organization of Logistics 6 (1), 2021, 85–95